Smart Hummingbird Feeder Manufacturing Process

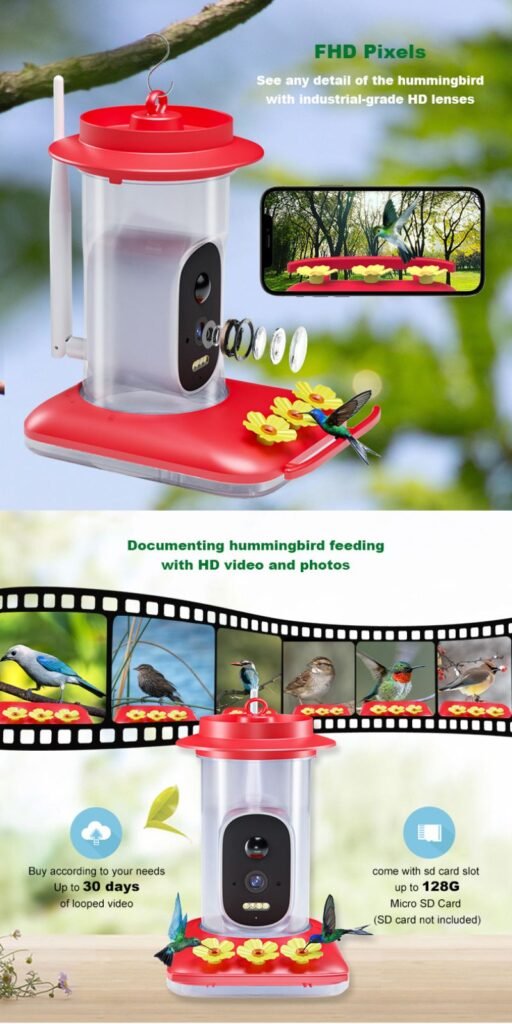

Design and Development:

Our team of designers and engineers works closely with clients to understand their specific needs, focusing on the unique requirements of a smart hummingbird feeder. We design the feeder to incorporate essential features like automatic feeding, remote monitoring, environmental sensing, and a bird-attracting mechanism. Using advanced design software, we create 3D models to ensure that both the appearance and functionality of the feeder are seamlessly integrated, making it not only user-friendly but also aesthetically pleasing.

Prototype Design and Testing:

Once the design is complete, we create prototypes to test the functionality of the smart features, including the automatic feeding system, hummingbird detection sensors, and wireless communication. This stage is crucial for fine-tuning the system to ensure reliable operation. The prototype undergoes extensive testing in simulated outdoor conditions to ensure its durability and performance in various weather conditions such as high heat, humidity, and wind. We focus particularly on ensuring the smart control systems, including wireless connectivity and sensor responsiveness, work flawlessly.

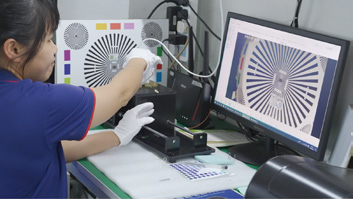

Component Sourcing and Inspection:

The smart hummingbird feeder relies on key components such as batteries, sensors, solar panels, and wireless communication modules. We work with global suppliers to source high-quality, environmentally-friendly components. Each part undergoes strict inspection, with a focus on durability and accuracy, especially the sensors and battery systems. These parts are tested for performance under a variety of environmental conditions to ensure they can operate reliably over time, even in harsh outdoor environments.

Assembly and Production:

Our state-of-the-art production facility is equipped with high-precision automated tools to assemble the smart hummingbird feeder. During the assembly process, we pay particular attention to the installation of the battery and the safety of the electronic circuits, as well as the proper alignment and secure attachment of the solar panel to ensure maximum energy efficiency. Special care is taken to ensure that the sensors and intelligent modules function correctly, accurately detecting hummingbird activity, while also ensuring the feeder is sealed to protect the electronics from environmental damage.

Quality Control and Testing:

Throughout the manufacturing process, we implement comprehensive quality control measures. In addition to the usual functional testing, we conduct detailed tests on the feeder’s smart features, including the stability of wireless signals, the sensitivity of the sensors, the accuracy of the automatic feeding system, and the efficiency of the solar charging system. The feeder undergoes rigorous testing in simulated outdoor environments to ensure it can perform reliably across various weather conditions, providing users with a dependable experience.

Packaging and Shipping:

Given the presence of electronic components and sensors in the smart hummingbird feeder, we strongly emphasize packaging protection. We use shock-resistant, moisture-proof materials to ensure the product remains intact during transit. After the final quality checks, the feeders are carefully packaged and prepared for shipping. We partner with trusted international logistics companies to ensure that each smart hummingbird feeder reaches customers worldwide safely and promptly, allowing them to enjoy the convenience and beauty of attracting hummingbirds to their gardens or outdoor spaces.